Case Study — Inspection of Painting Canvases with Ai1 and Medusa

Application Context

A company specialized in the production of painting canvases for the fine arts sector implemented an automated computer vision-based quality inspection system to ensure the absence of surface and structural defects before packaging.

Objectives

- Detect surface defects using reflective lighting and internal imperfections using transmission lighting.

- Automate the quality control process to increase efficiency and reduce waste.

- Classify defects by type and location, enabling corrective actions or automatic rejection.

Technical Solution

The system is based on a customized Ai1 module running proprietary Medusa software, equipped with 9 area-scan cameras (3.2 MPixel) and a dual lighting system for both reflection and transmission.

- 9 synchronized area-scan cameras (3.2 MPixel each)

- Dual LED lighting:

- Top (reflection) to detect visible defects such as smears, folds, and contamination

- Bottom (transmission) to detect holes, broken fibers, and internal stains

- Real-time processing using Ai1 and Medusa on edge hardware

- Image acquisition synchronized with linear encoder and trigger signals

Defects Detected

- Micro-holes not visible to the naked eye (detected via transmission)

- Ink smears, halos, and contamination

- Longitudinal and transversal folds

- Broken fibers or irregular textile density

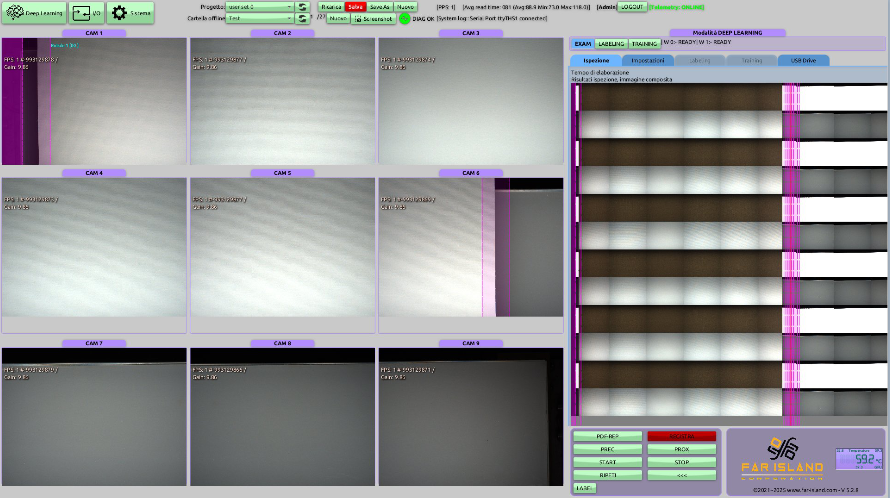

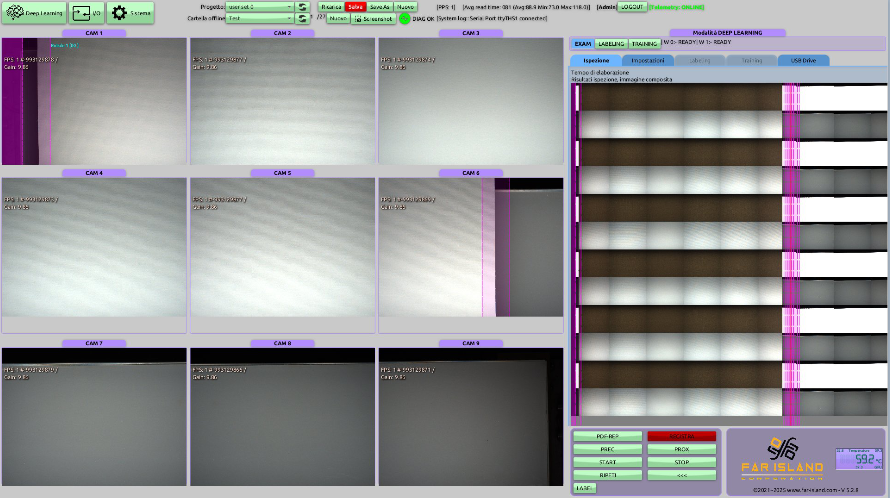

Example from Medusa Software

Below is a real screenshot of the Medusa software inspecting a painting canvas:

Learning and Adaptability

The system is designed to evolve alongside production:

- The customer can autonomously update the AI model as new defect types are discovered.

- Each labeled defect is included in incremental training, improving recognition accuracy over time.

Thanks to the flexibility of Medusa:

- Users can define custom inspection profiles based on geometric characteristics of defects (width, height, area).

- It is possible to create quality filters for different acceptance levels, from museum-grade to industrial tolerance.

Results

| Indicator | Before | After Ai1 + Medusa |

| Manually rejected products | 6.8% | 0.9% |

| Average inspection time (manual) | ~18 sec | < 3 sec |

| Undetected defects | Not tracked | < 0.5% |

Line Integration

- Digital output for conveyor stop in case of critical defect

- Automatic image logging for defect traceability

- User-friendly interface for profile and recipe management

Flexibility

The system is designed to handle various canvas formats with minimal hardware modifications. Thanks to Medusa:

- Users can configure quality thresholds and inspection profiles independently

- The AI adapts automatically to different weaves, thicknesses, and transparency levels