Products

Solutions

In the world of automated industrial production, optical inspections with computer vision systems are essential to ensure product quality, compliance, and reliability. In high-criticality sectors like automotive or energy storage, where even the slightest imperfection can affect safety, inspection accuracy becomes a competitive lever.

When choosing vision software, many companies rely on established industrial suites. However, more and more operators are turning to tailor-made solutions: custom-developed vision systems designed to meet the specific needs of the production process.

| Aspect | Off-the-Shelf Industrial Suite | Tailor-Made Solution |

|---|---|---|

| Stability | High, tested in regulated environments | High, if developed on solid specifications |

| Flexibility | Limited: standardized configuration | Maximum: open and modular architecture |

| Product Adaptability | Partial: requires compromises or external adjustments | Total: built around actual geometry and defectology |

| Artificial Intelligence | Available but often not very accessible or customizable | Integrated and adapted to defect type and process logic |

| Maintenance | Centralized, bound to the supplier | Customizable based on SLAs and internal skills |

| Integration with Business Systems | Limited or sold separately | Complete, with direct interfaces to MES, ERP, or local DBs |

A company specializing in metal housings for lithium batteries compared two solutions for the optical inspection phase:

Production lines are increasingly dynamic. Part geometries, materials, and acceptance criteria change constantly. A rigid suite often hinders adaptation. A custom solution, instead, allows for quick and controlled interventions without starting from scratch each time.

A tailor-made software is not just a technical system: it's a strategic asset. It allows you to define rules that reflect the production reality, generate targeted reports, and evolve the system autonomously over time.

Tailor-made solutions represent a choice of autonomy, responsiveness, and precision. When product quality depends on the ability to detect specific defects and quickly adapt to changes, a custom-built system proves to be the most robust and sustainable choice.

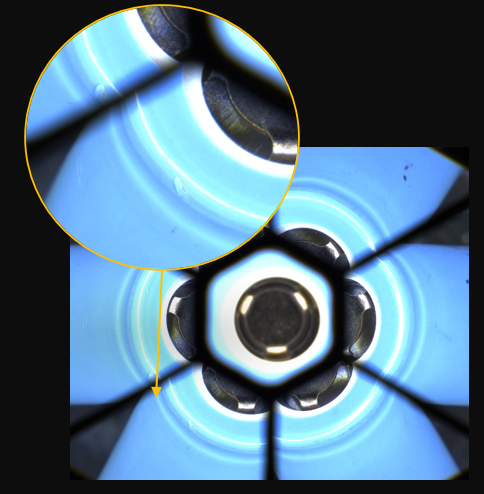

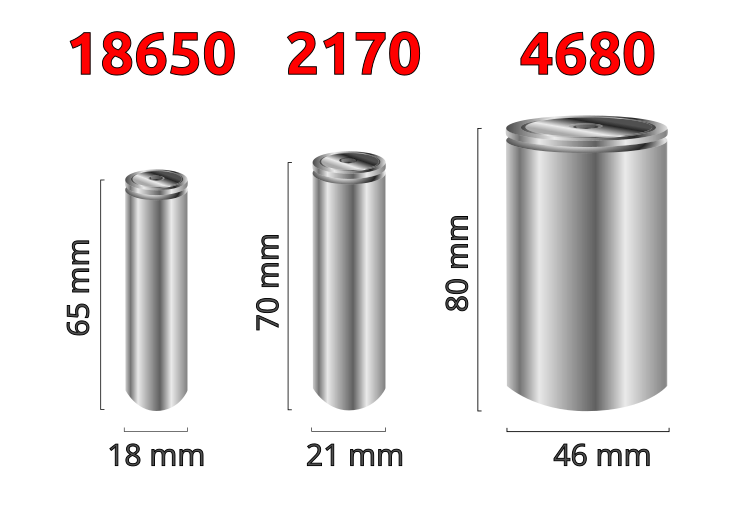

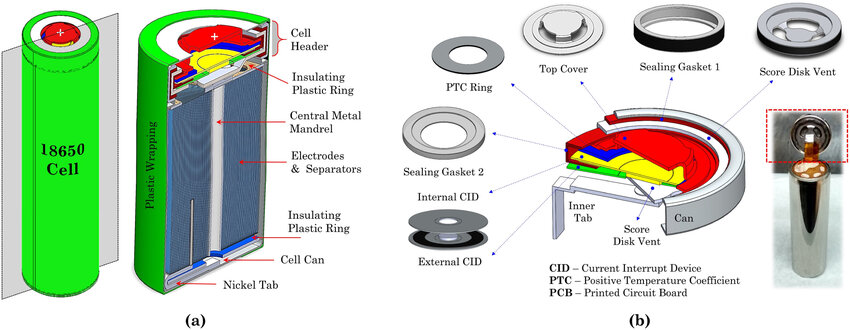

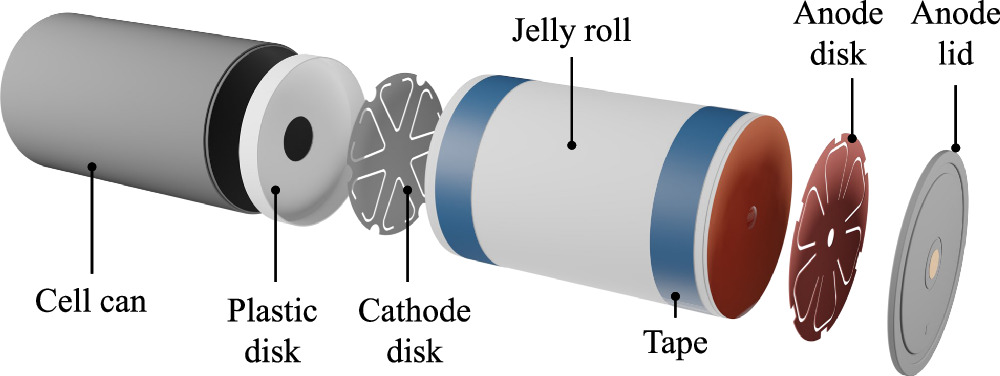

Battery cans of various formats have been inspected for their multiple components and at various stages of production.

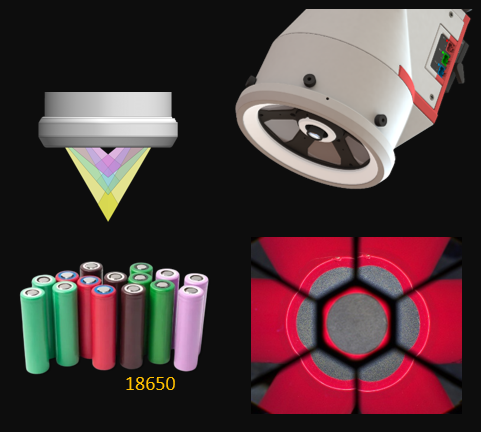

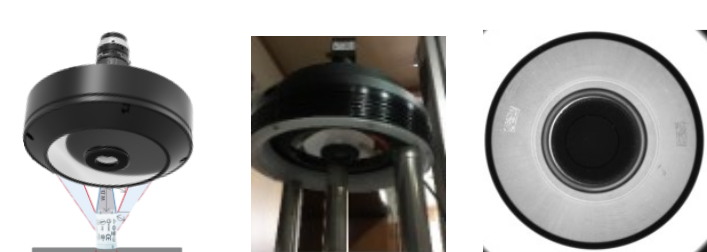

Overview of the possible optics to be used for the 360 degrees inspection of batteries and their components.

Battery’s shrink wrap inspection