Products

Solutions

Dental implants are high-precision medical devices designed to integrate safely and permanently into the human body. In this context, quality control is not just a production step — it's a critical safety and performance requirement.

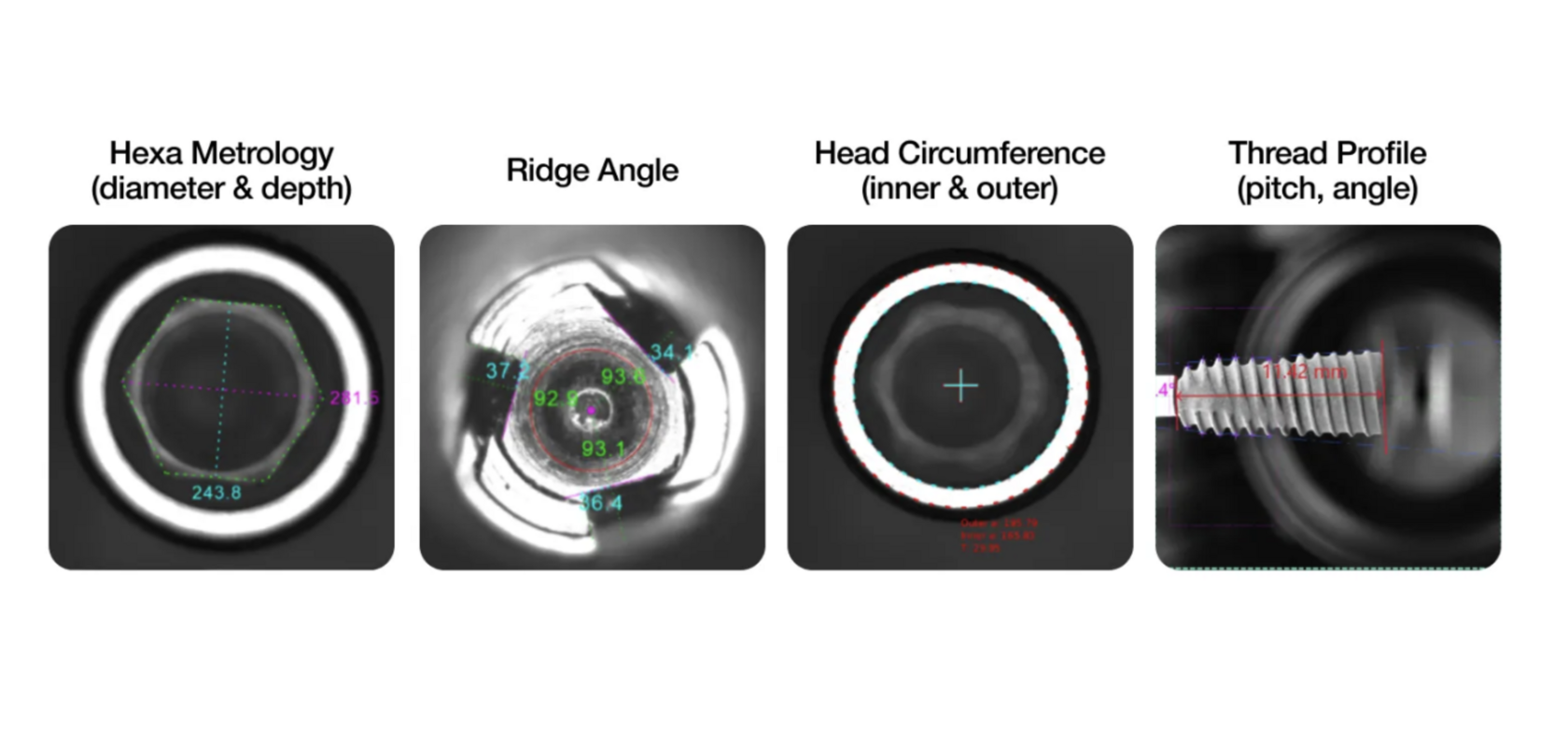

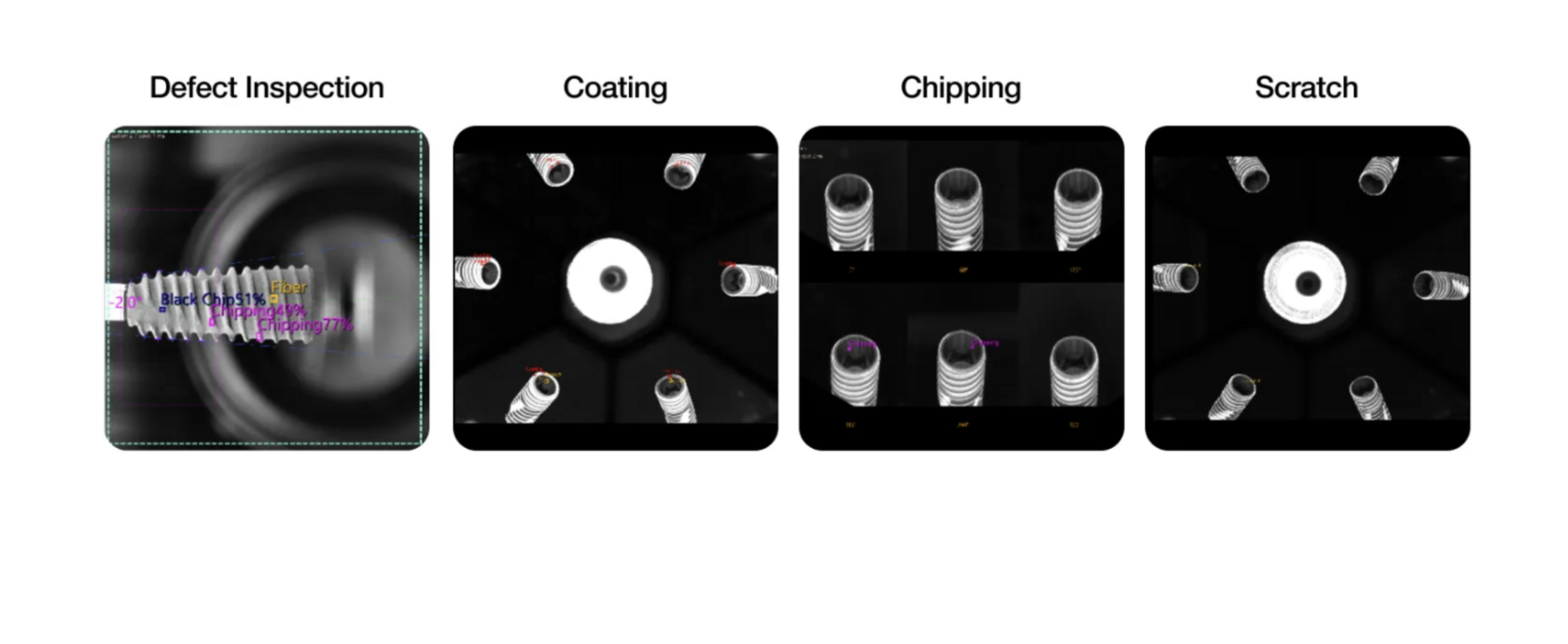

Their complex geometry, micro-threaded surfaces, and advanced coatings make inspection extremely delicate. Invisible or sub-tolerance defects can affect osseointegration and lead to post-operative complications.

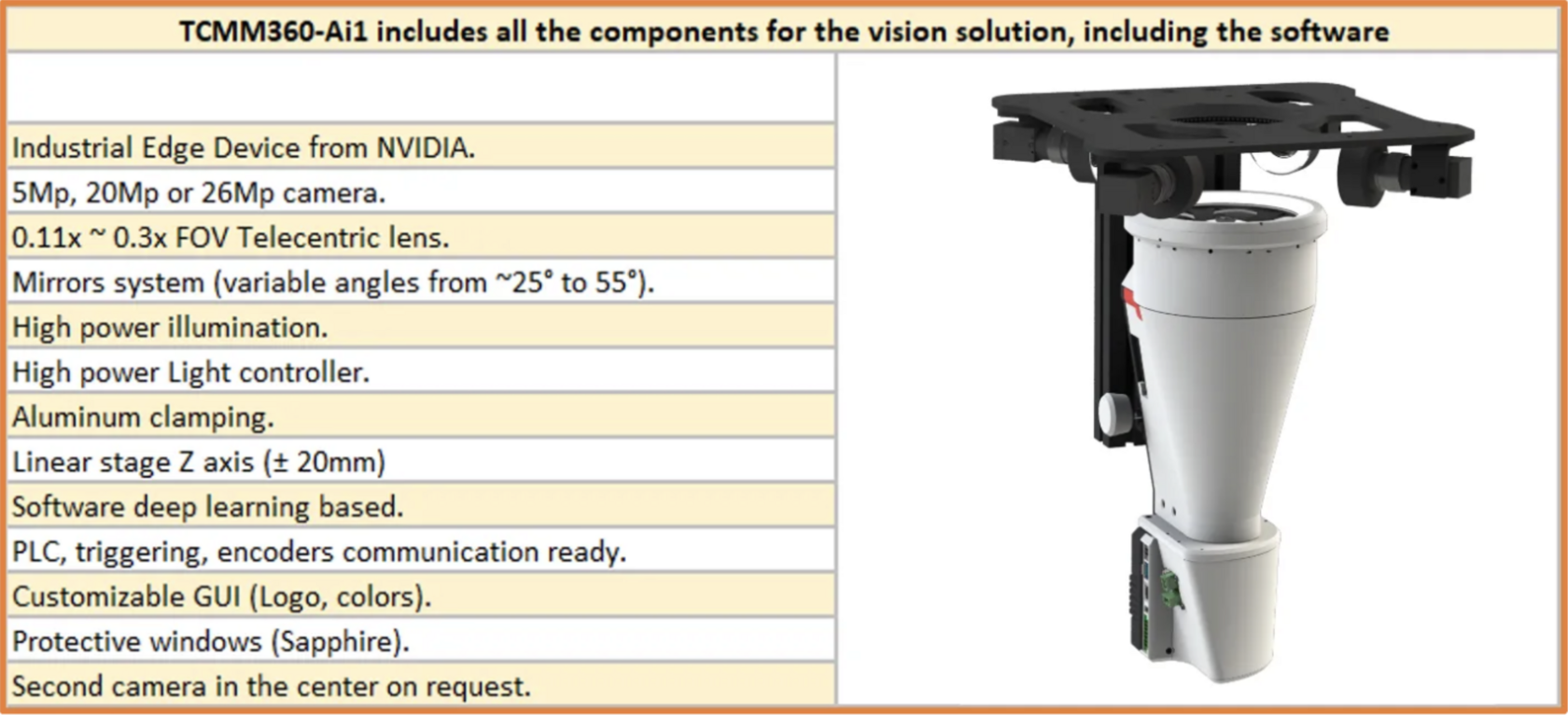

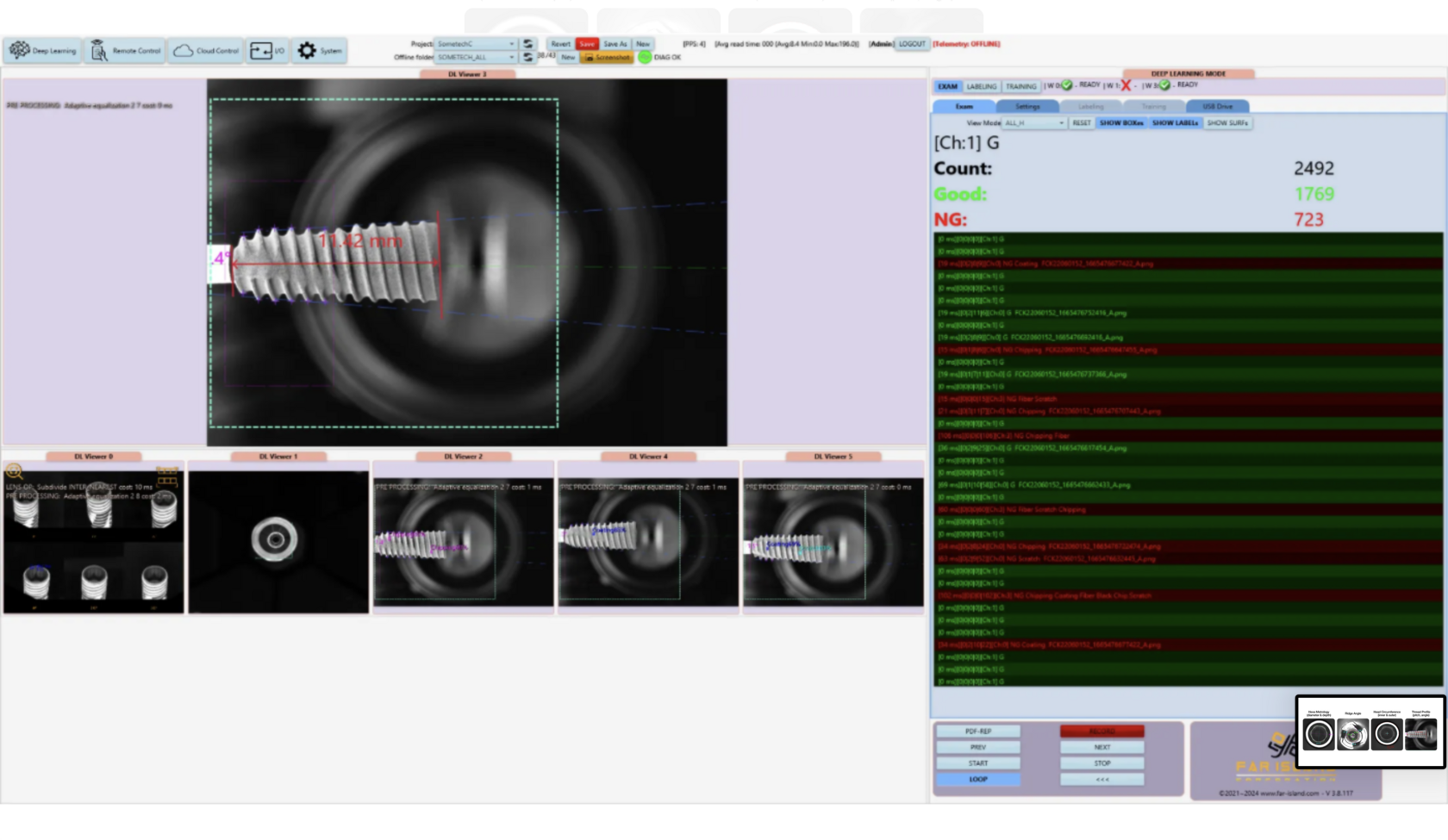

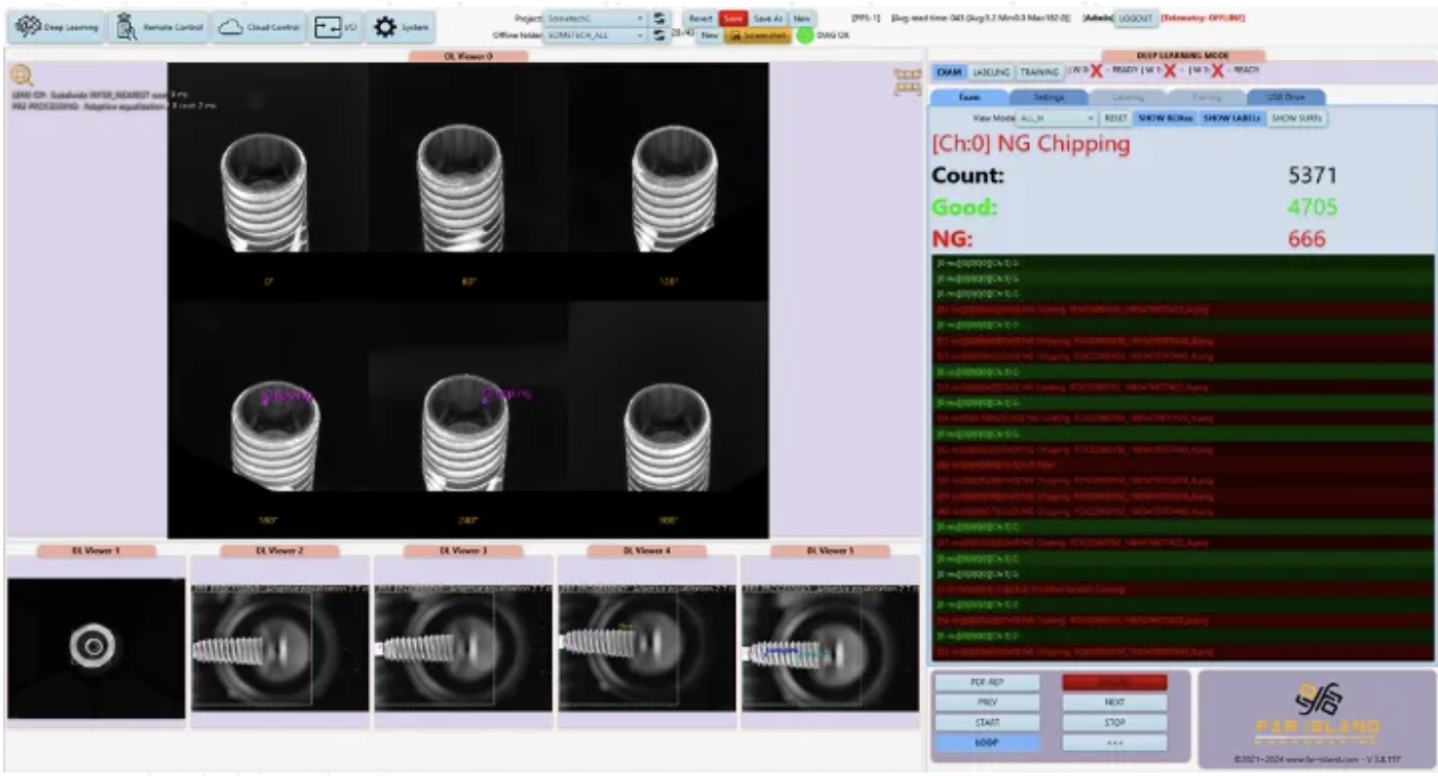

To meet this challenge, we developed Ai1 All-In-One, a compact inspection system equipped with onboard Medusa software, optimized for real-time defect detection using advanced deep learning algorithms.

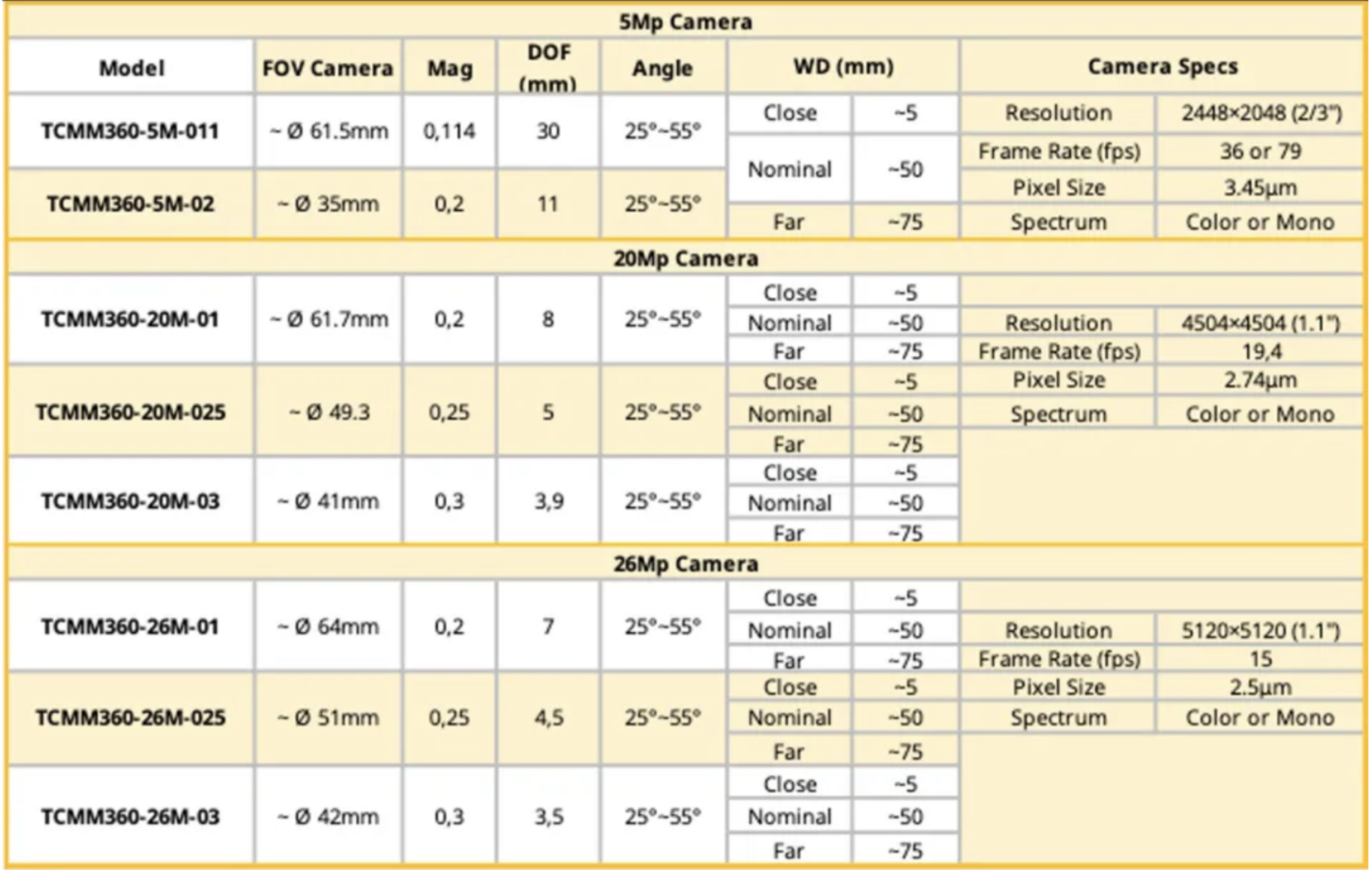

The system uses a multi-mirror Ai1 configuration to inspect the internal and bottom surfaces of the implant. This is complemented by 4 lateral cameras for inspecting the full thread along the side without the need for mechanical rotation.

Medusa runs three dedicated inference models in parallel, each trained to identify critical defects specific to one zone: external surface, internal core, and bottom edge.

The system is also capable of detecting the pickup angle of the implant by the robot and sending correction values in real time, so the part can be reoriented to be perfectly perpendicular to the optical axis.

In this project, the system integrator used a custom control application built in LabVIEW, communicating with Medusa via Ethernet API for real-time alignment and coordination.

| Indicator | Before | With Ai1 + Medusa |

|---|---|---|

| Subjective variability | High | Eliminated |

| Defect detection accuracy | ~84% | >99.5% |

| Total inspection time | n/a | < 1 second |

Currently, four Ai1 All-In-One systems with Medusa are in operation at OSSTEM IMPLANT’s Busan facility, fully integrated into live production lines.

Far Island Corporation Ltd. develops total quality control automation solutions. We deliver All-in-One vision systems for implant inspection to KOSDAQ-listed companies.