Products

Solutions

Medusa is a comprehensive software platform developed to meet the growing demand for intelligent visual inspection, measurement, and automation in industrial environments. Designed around the latest advances in artificial intelligence, Medusa offers a unified and modular solution that integrates all essential components of a modern machine vision system, from data labeling to model inference and dimensional analysis.

With its no-code architecture and intuitive user interface, Medusa enables companies to deploy high-performance visual systems without the need for specialized programming skills. Its flexibility and scalability make it suitable for both small-scale setups and complex industrial lines.

Medusa supports a wide range of visual inspection and automation tasks. These include dimensional measurement, detection of surface defects such as cracks or scratches, and object counting in high-speed environments. It also enables AI-based guidance for pick-and-place systems, anomaly detection based on unsupervised learning, and verification of the presence or absence of components in complex assemblies. These functionalities are built on a common platform that allows them to be combined and configured according to the specific needs of each production scenario.

The AI engine at the core of Medusa leverages open-source deep learning models, which are internally optimized to meet industrial requirements in terms of reliability, speed, and accuracy. Users can choose from a range of pre-trained models or build custom ones from scratch using dedicated training pipelines provided within the platform. Depending on the application, it is possible to prioritize inference speed or accuracy through configurable performance profiles.

Medusa supports various model types, including binary classification for simple pass/fail decisions, object recognition for multi-class detection, oriented bounding boxes for rotation-sensitive tasks, and instance segmentation for pixel-level object distinction. This variety ensures precise adaptation to use cases across different industries.

AI training output example with 99% accuracy on production data

The software is available for both Windows and Linux systems and is fully compatible with edge devices, allowing users to run inspections directly on the production floor with minimal latency. This flexibility makes Medusa suitable for integration in centralized control systems as well as distributed edge-based deployments.

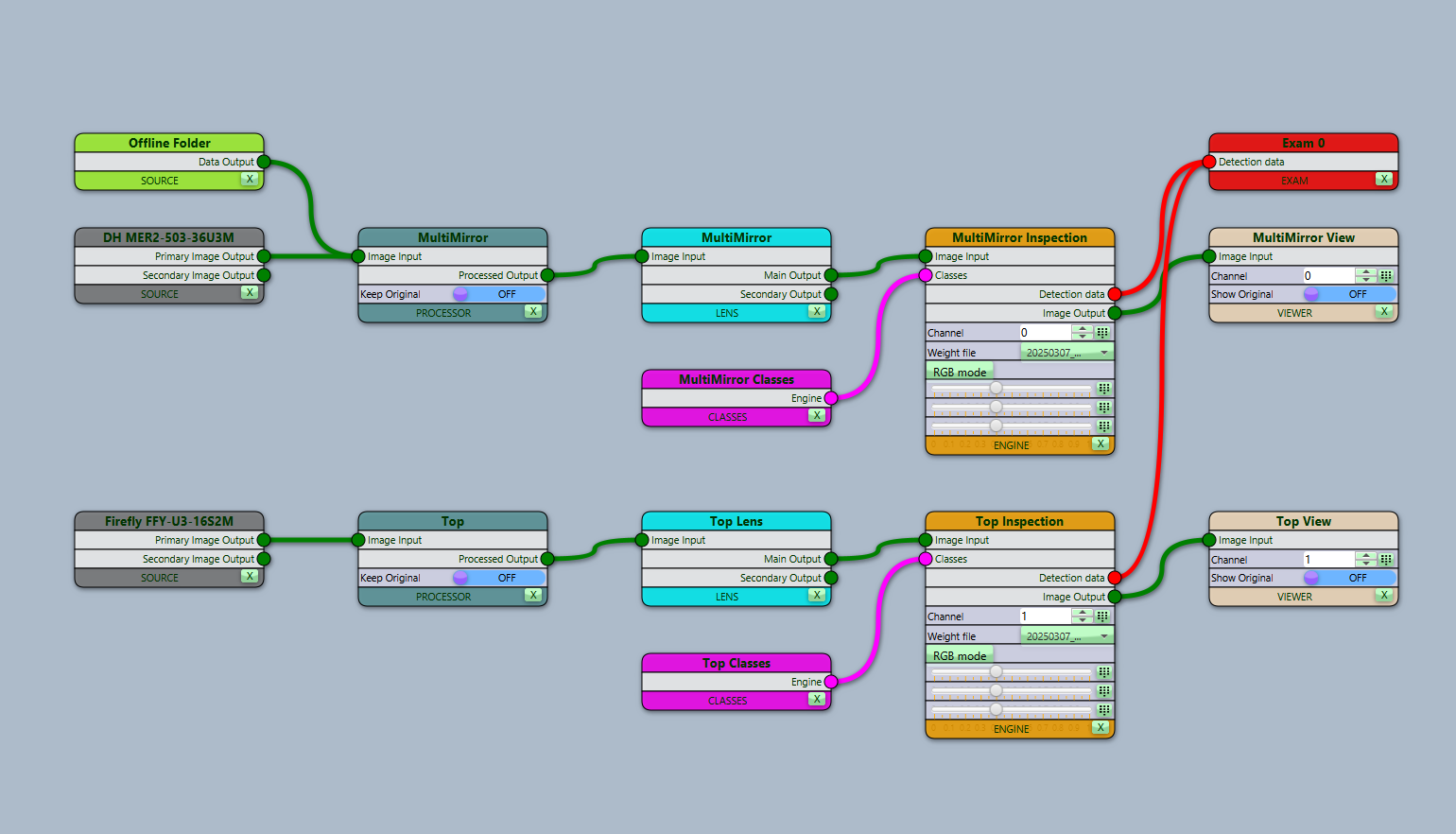

Medusa features a graphical drag-and-drop interface that enables full configuration of inspection workflows without writing code. The platform is multilingual and offers customizable visual themes, allowing it to adapt to the preferences and habits of different users or organizations. Thanks to its accessibility, Medusa can be used by technical operators, engineers, and production staff alike.

Node-based architecture for data flow configuration and modular system design

Designed to integrate seamlessly into industrial environments, Medusa provides a complete set of communication options. A comprehensive TCP/IP API allows easy connection with external platforms, while native support for RS232, Ethernet, CANbus, and RS485 ensures direct integration with PLCs and automation systems. This makes Medusa fully compatible with SCADA, MES, and other factory-level control systems.

Industrial-grade onboard connectivity for PLC and field integration

Medusa is currently deployed in a variety of sectors, including automotive manufacturing, pharmaceutical production, fastener sorting (such as screws, bolts, and nails), food and beverage processing, and lithium battery manufacturing. Its modular structure and adaptable AI models also make it suitable for electronics, packaging, logistics, and general-purpose manufacturing, confirming its position as a truly cross-sector solution.

The platform includes automated reporting tools that allow users to generate inspection summaries in PDF format and export structured data in CSV for further analysis. Custom export formats can be implemented upon request, ensuring seamless integration with enterprise software or regulatory requirements.

Medusa includes a built-in telemetry system that monitors system performance in real time. This enables remote diagnostics, live performance tracking, and proactive maintenance. Telemetry data can be used to optimize inspection strategies and prevent production issues before they escalate. Training and onboarding services are also available to support customers during initial setup and long-term operation.

Medusa is distributed under a perpetual license, providing customers with full control over the installation and use of the software without recurring subscription fees. Thanks to its modular architecture, customers can choose to license only the features they need—such as inference, labeling, or dimensional analysis—allowing for gradual investment and tailored system design.