Products

Soluzioni

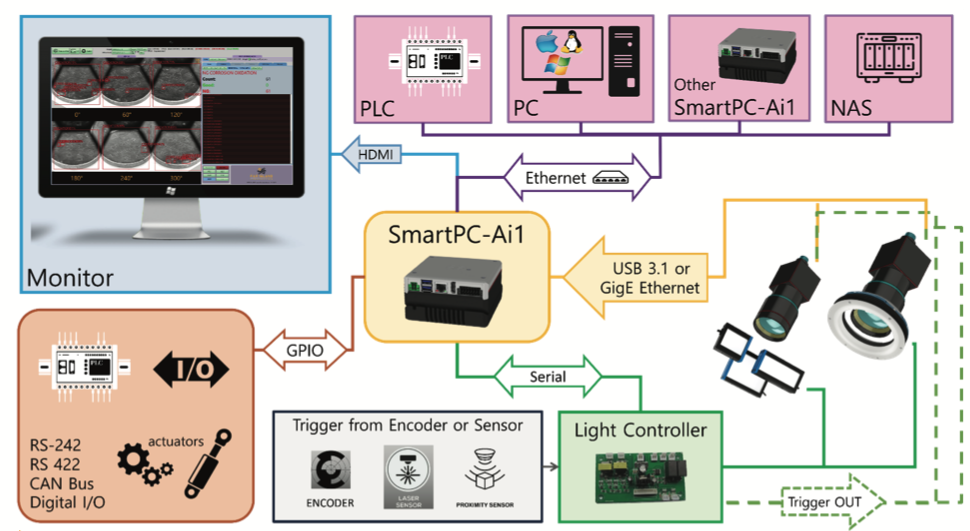

Our main customers requested a new device that could solve common problems in the Industrial Computer Vision field: durability, simplicity of deployment, ultra-compact design, and top performance.

So we designed the SmartPC-Ai1 to solve the challenges we face in Industrial Computer Vision.

A Total, All-in-One, Plug & Play Vision Solution that integrates optical systems, deep-learning software, illuminations, and a powerful AI edge device into a simple, unified form factor. It means no more hundreds of different cables to choose and connect, no more different vendors for different parts of the vision system, no more dozens of different failure points to analyse in case of an incident.

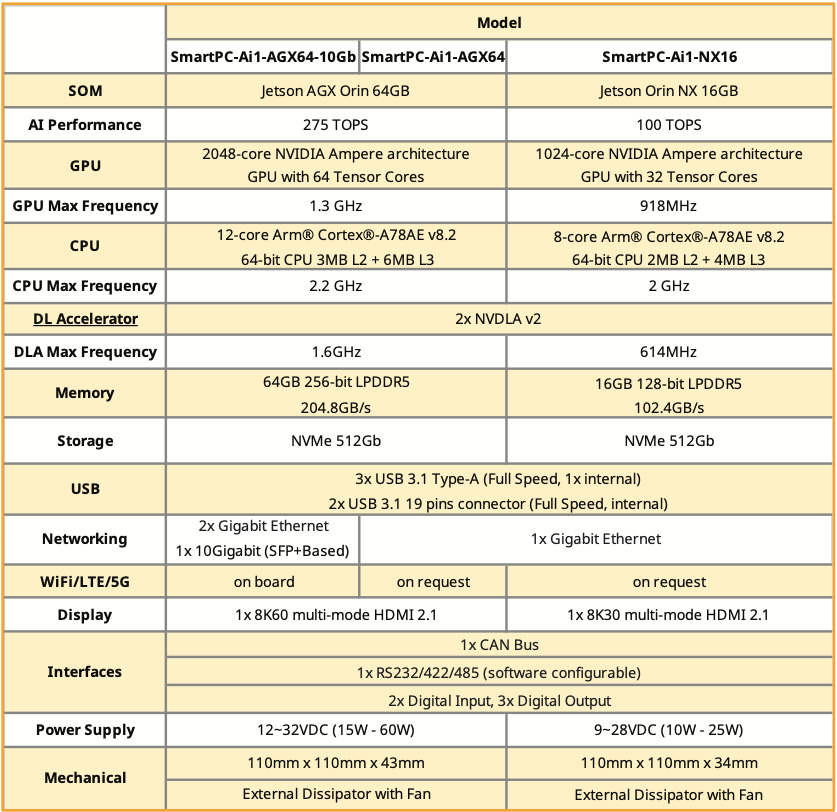

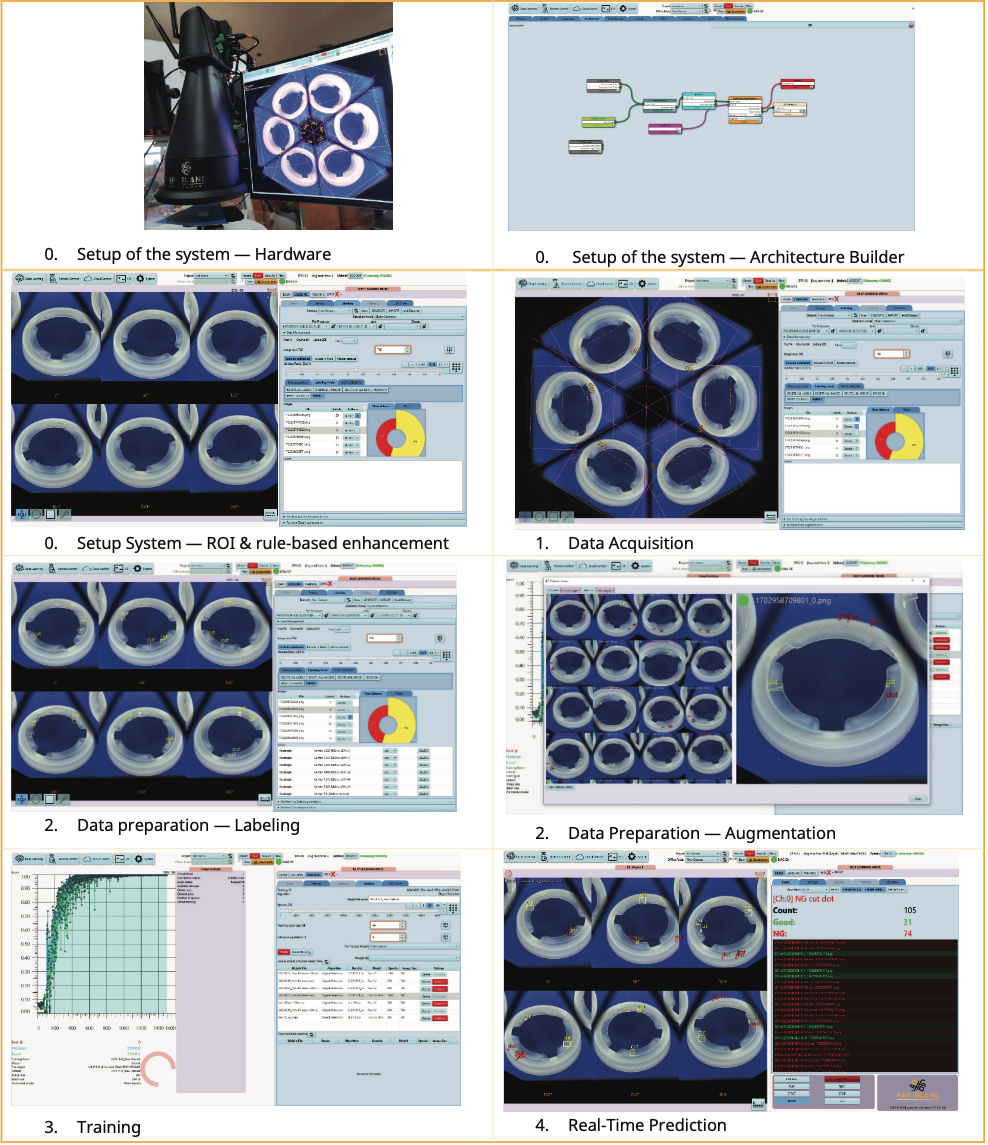

At the heart of the SmartPC-Ai1 Series, there is the SmartPC-Ai1 Standalone, an edge device with highly optimized built-in software, enhancing operational efficiency in edge computing. It can transform any system into a state-of-the-art deep learning-based solution in a few minutes. The optical system is from famous Italian brand Opto Engineering, while the computing power comes from NVIDIA AI-Edge devices (8-cores and 12-cores). The high-power illumination is handled by an internal controller and totally managed by onboard software.

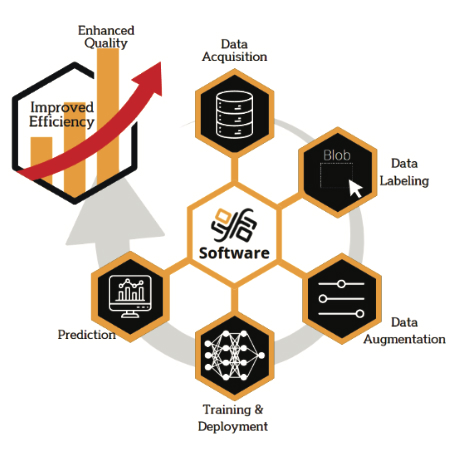

Another innovation that we introduced is the automated remote cloud training. Training task for Deep Learning is a big resource and time-consuming task. The traditional approach solves this problem with very expensive workstations that are good for training but overpower all the other tasks. We removed this requirement from the on-site production device, which now can be robust, fast for inference and low cost. After the labeling, the dataset is transferred to the cloud in a click of a button and the training starts automatically. When the training is completed by our powerful servers, the inference-model is transferred back to the production device, and the operations can start.

Our solution is to cook for you all the needed components assembled, tested and ready to use in a compact and flexible system that we call SmartPC-Ai1. Ai1 stands for All-in-One, while simultaneously highlighting its powerful AI capabilities.

| Innovative | No-code Deep Learning-based software included. Acquisition -> Labeling -> Training -> Prediction all GUI based. |

| Robust | Rugged hardware with industrial compliant connectors and opto-isolated GPIO. |

| Fast | Based on AI Supercomputers in 2 different configurations 8-cores and 12-cores. |

| Compact | Made to fit impossible places. |

| Scalable | One-Man integration (replace an entire vision system team) |

Easy to set up like a smart camera, but powerful like a computer, this innovative solution has many key advantages:

Our solution is to cook for you all the needed components assembled, tested and ready to use in a compact and flexible system that we call SmartPC-Ai1. Ai1 stands for All-in-One, while simultaneously highlighting its powerful AI capabilities.

| Innovative | No-code Deep Learning-based software included. Acquisition -> Labeling -> Training -> Prediction all GUI based. |

| Robust | Rugged hardware with industrial compliant connectors and opto-isolated GPIO. |

| Fast | Based on AI Supercomputers in 2 different configurations 8-cores and 12-cores. |

| Compact | Made to fit impossible places. |

| Scalable | One-Man integration (replace an entire vision system team) |

Easy to set up like a smart camera, but powerful like a computer, this innovative solution has many key advantages:

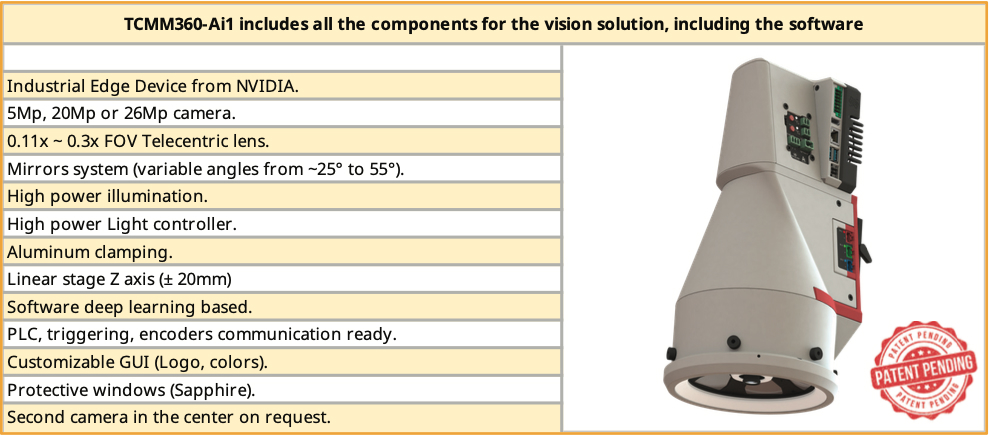

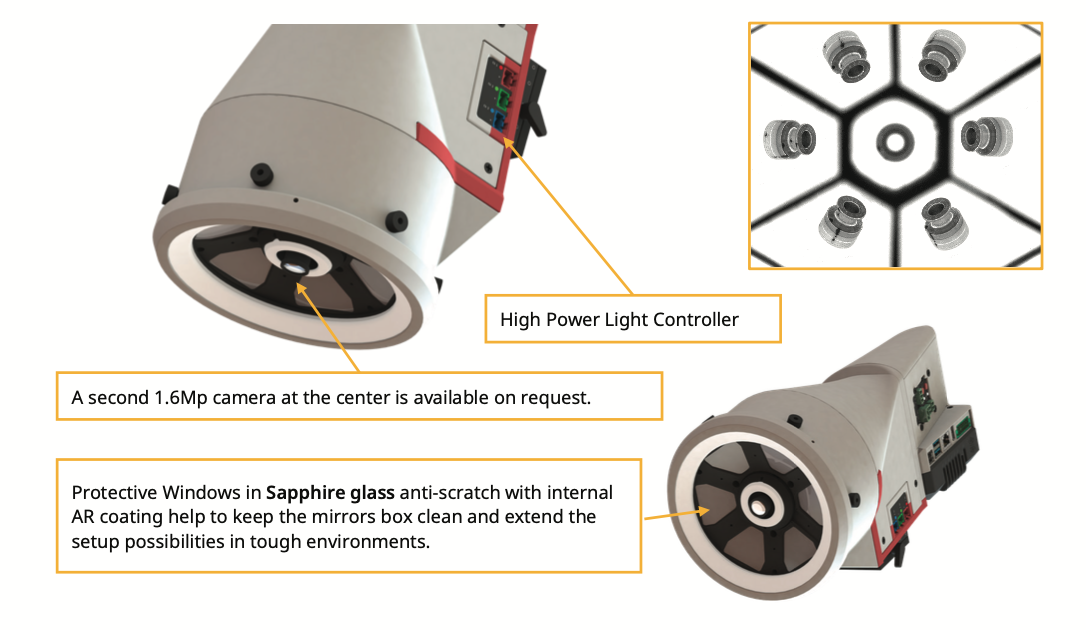

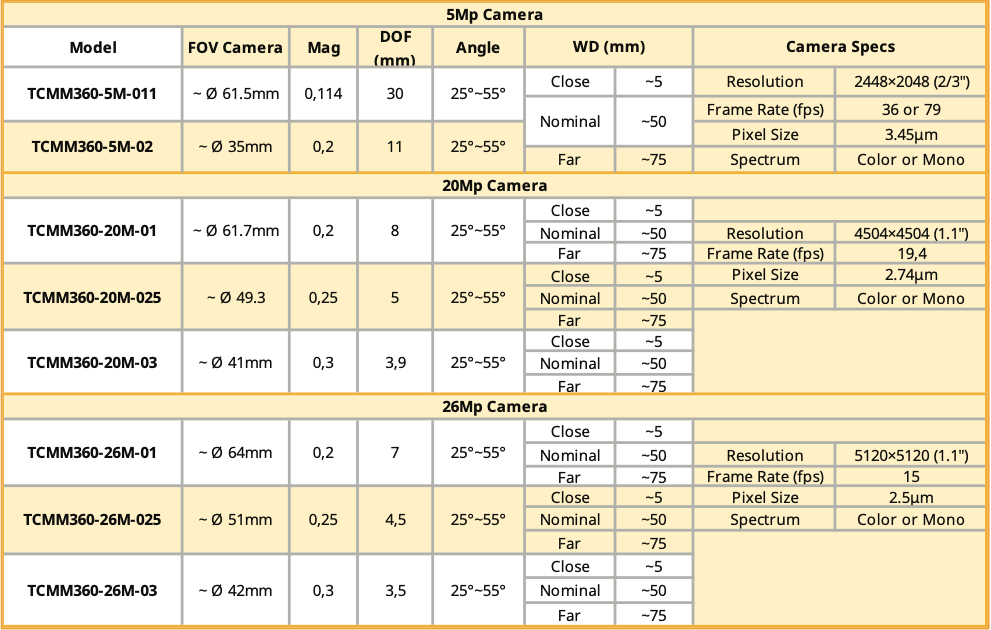

TCMM360-Ai1 is a total vision solution for inspection and quality control of objects from multiple views using a single shot.

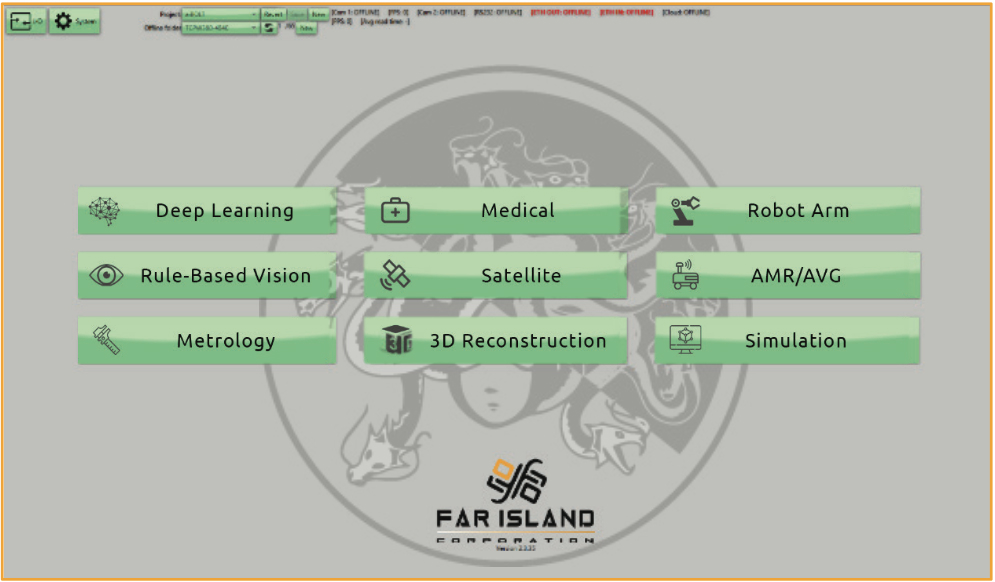

The software is divided into modules available to buy separately based on the users' needs. The possible applications go from machine vision to 3D reconstruction, from satellite to medical image processing and much more.

The standard software included in the SmartPC-Ai1 has on-device everything needed to develop the vision solution on any possible optical system. CCTV, Telecentric, Multi-Mirrors, Hypercentric, Catadioptric, pinhole, probes, are selectable from the GUI. This includes adjustments for the ROI size, position, the number of mirrors, unwrapping tools, and more. Additionally, the GUI integrates all necessary hardware peripherals and communication interfaces for interacting with the external world, ensuring a ready-to-use experience.

The fully GUI-based approach requires no coding skills and empowers anyone with state-of-the-art tools to develop a Deep Learning-based inspection solution in a few hours.

Total Vision solution for inspection and quality control of 360 degrees side view of an objects using a single shot.